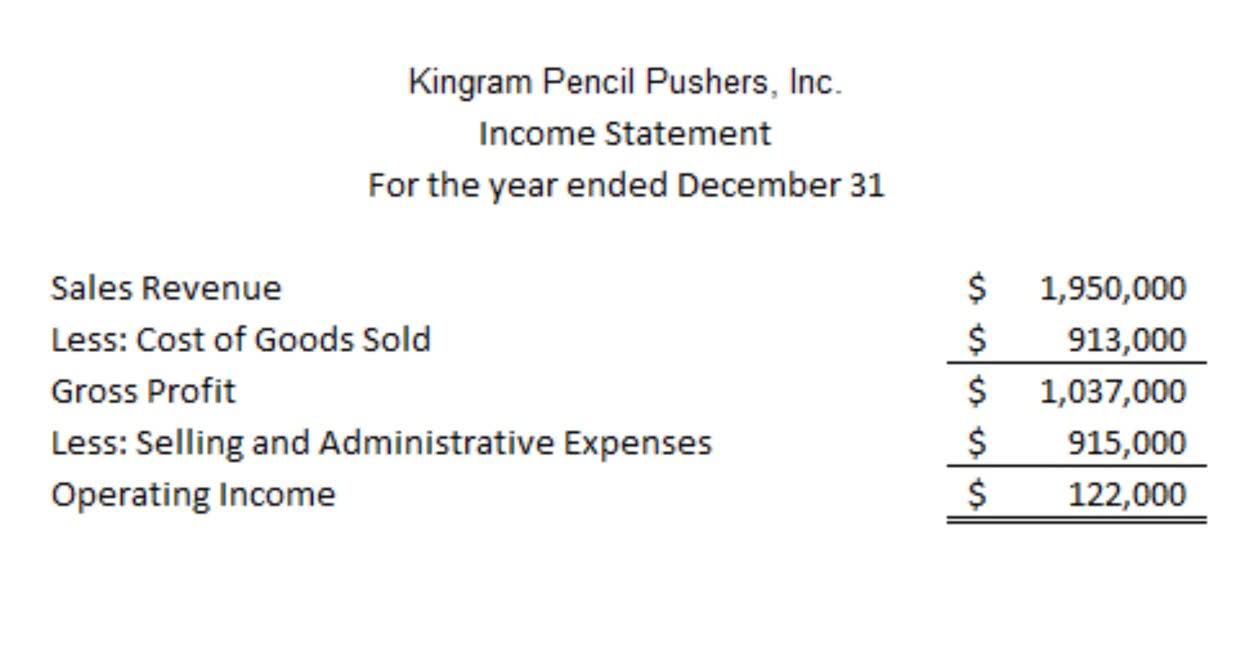

Companies need to make certain the sales price is higher than the prime costs and the overhead costs. In some industries, the company has no control over the costs it must pay, like tire disposal fees. To ensure that the company is profitable, an additional cost is added and the price is modified as necessary. In this example, the guarantee offered by Discount Tire does not include the disposal fee in overhead and increases that fee as necessary.

- Another way to view it is overhead costs are those production costs that are not categorized as direct materials or direct labor.

- However, there is a strong need to constantly update the production level depending on the seasonal fluctuations and the factor affecting the demand of the product.

- Thus the organization gets a clear idea of the expenses allocated and the expected profits during the year.

- The predetermined overhead rate computed above is known as single or plant-wide overhead rate which is mostly used by small companies.

- In real life, overhead allocation is a tool used by many businesses across multiple sectors for proper cost accounting and financial reporting.

- The estimated manufacturing overhead cost applied to the job during the accounting period will be 1,494.

Example 2: Cost per Hour

It’s also important to note that budgeted figures in calculating contribution margin overhead rates are used due to seasonal fluctuation/expected changes in the external environment. Carefully tracking overhead expenses is key for small businesses to optimize costs. This involves categorizing all overhead costs and regularly analyzing them to identify potential savings. Knowing the overhead cost per unit allows the business to set competitive pricing while still covering their indirect expenses. The key is choosing an appropriate cost driver – like machine hours in manufacturing or headcount in sales – to distribute overhead expenses. Calculating overhead rates accurately is critical, yet often confusing, for businesses.

Conclusion: Mastering Overhead Rate Calculation for Improved Financial Health

This means that for every hour of work the marketing agency performs, it will incur $20 in overhead costs. The best way to predict your overhead costs is to track these costs on a monthly basis. On the other hand, if the business wants to use actual overheads, it has to wait for the end of the month and predetermined overhead rate get invoices in hand. So, it may not be a good idea with perspective to effective business management. The business is labor-intensive, and the total hours for the period are estimated to be 10,000.

- To calculate a predetermined overhead rate, estimate overhead costs, estimate activity level, and divide the estimated overhead costs by the estimated activity level.

- In order to estimate the predetermined overhead rate it is first necessary to to decide on an activity base on which to apply overhead costs to a product.

- The manufacturing plant requires 1000 labor hours to manufacture 500 units of a specific product, which we assume as product X.

- Plus, the information can be used in pricing decisions and profitability analysis of each product.

- Two companies, ABC company, and XYZ company are competing to get a massive order that will make them much recognized in the market.

Determining Estimated Overhead Cost

When companies begin the Budgeting for Nonprofits planning process of manufacturing a product, cost projections are a large and important focus. Calculating a predetermined overhead rate is one of the first tasks management will take on because it provides a formula to estimate the production costs of a product in advance. Specifically, the predetermined overhead rate is an approximated ratio of manufacturing overhead costs determined in advance based on variable and fixed costs.

Forecast future overhead costs based on historical data, industry trends, and expected changes in production volume. This option is best if you’re unsure of how to calculate your predetermined overhead rate or if you don’t have the time to do it yourself. It’s a completely estimated amount that changes with the change in the level of activity.

Practical Application of Overhead Rates in Business

- A business needs to estimate its total overheads for a period and estimate its total units or activity basis for the predetermined overhead rates.

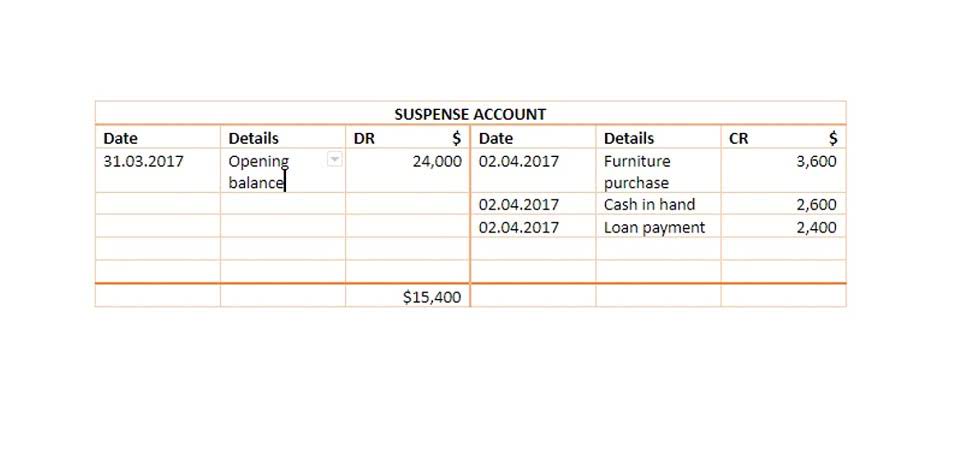

- This is calculated at the start of the accounting period and applied to production to facilitate determining a standard cost for a product.

- In this article, we will discuss the predetermined overhead rate, why it matters, and how to calculate it.

- Larger organizations may employ a different predetermined overhead rate in each production department, which tends to improve the accuracy of overhead application by employing a higher level of precision.

- Direct costs include direct labor, direct materials, manufacturing supplies, and wages tied to production.

For example, assume a company expects its total manufacturing costs to amount to $400,000 in the coming period and the company expects the staff to work a total of 20,000 direct labor hours. In order to calculate the predetermined overhead rate for the coming period, the total manufacturing costs of $400,000 is divided by the estimated 20,000 direct labor hours. While predetermined overhead rates are widely used and needed for businesses, they may have some limitations. A business needs to estimate its total overheads for a period and estimate its total units or activity basis for the predetermined overhead rates.

- This rate is then applied to actual production or service delivery, allowing businesses to assign overhead costs accurately.

- This allows businesses to capture the full cost of production in their accounting.

- It’s essential to fully understand the allocation base and allocation rate or variance for the predetermined overhead rate.

- One of the key elements in determining the overhead rate is calculating direct labor hours.

- Before jumping to detail, let’s go through the basic overview and key definition first.

- For a deeper appreciation and understanding of the concept of overhead allocation, tangible examples can be incredibly helpful.

Activity and Cost Bases

The most important step in calculating your predetermined overhead rate is to accurately estimate your overhead costs. Businesses rely on the predetermined overhead rate to accurately estimate costs, set competitive prices, and make informed financial decisions. Many accountants always ask about specific time which we need to do this, at what point in time is the predetermined overhead rate calculated. The predetermined rate usually be calculated at the beginning of the accounting period by relying on the management experience and prior year data. Using the predetermined overhead rate formula and calculation provides businesses with a percentage they can monitor on a quarterly, monthly, or even weekly basis.

For a deeper appreciation and understanding of the concept of overhead allocation, tangible examples can be incredibly helpful. These examples are meant to better illustrate what we’ve discussed about overhead allocation in the world of business, showing how these concepts are put into practice. Overhead cost allocation is much more than merely using math to distribute costs. It’s an integral part of financial decision-making, pricing strategy, and profitability analysis of a company. When it comes to managing a business, mastering every aspect of your financials is vital.